Mobile

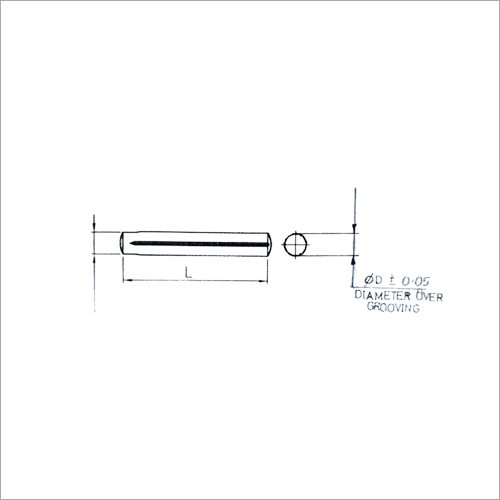

08045478520Grooved Dowel Pin

Product Details:

- Surface Treatment Galvanized

- Grade 316,SS 304,316 L

- Feature Smooth

- Hardness High

- Shape Round

- Finish Smooth

- Usage Construction

- Click to View more

Grooved Dowel Pin Price And Quantity

- 1000 Piece

- 10 INR/Piece

Grooved Dowel Pin Product Specifications

- Smooth

- Round

- High

- Steel

- 316,SS 304,316 L

- Gray

- Industrial

- Galvanized

- Smooth

- Construction

Grooved Dowel Pin Trade Information

- Cash in Advance (CID), Cash on Delivery (COD), Cheque

- 100000 Piece Per Month

- 15 Days

- All India

Product Description

With three parallel grooves, this Grooved Dowel Pin is a sturdy press-fit fastening. This pin causes a void by displacing material inside the pin. The utilization of this dowel pin is required in a variety of common applications, such as locking mechanisms, swivels, pulleys, and finding elements. This Grooved Dowel Pin has a number of benefits, such as the ability to groove only a portion of its length and the fact that it does not require a precisely reamed hole.

We offer a comprehensive range of Grooved Dowel Pins that are fabricated using premium quality materials and according to the international quality standards. These are available in various specifications and can be custom designed according to the needs of the clients. These are accessed at reasonable prices in the market.

We offer our clients a wide gamut of Grooved Dowel Pins that is highly recognized for easy fastening, rust resistance, durability and high strength. The offered products are designed by our professionals in complete compliance with the defined industry standards. In addition, to ensure that the offered products are free from any kind of defect and are perfect in all respect, our quality controllers perform a variety of tests on it. Our clients can avail these Grooved Dowel Pins in various specifications at economical prices.

Features of Grooved Dowel Pin:

- High Durability

- Corrosion Resistance

- High Tensile Strength

- Dimensional Accuracy

FAQs of Grooved Dowel Pin:

What is a Grooved Dowel Pin?

A grooved dowel pin is a kind of latch used to adjust and get parts in mechanical gatherings. It highlights at least one furrows along its length, which assist with working on its maintenance and forestall turn inside an opening.

How Does a Grooved Dowel Pin Work?

The furrows on a grooved dowel pin interlock with the material of the opening it's embedded into. This forestalls the dowel pin from turning inside the opening, giving a steady arrangement and decreasing the gamble of dismantling because of revolution.

Where Are Grooved Dowel Pins Utilized?

Grooved dowel pins are ordinarily utilized in applications where exact arrangement and protection from pivot are basic. They are tracked down in different ventures, including auto, aviation, assembling, and apparatus.

How Are Grooved Dowel Pins Introduced?

Grooved dowel pins are embedded into adjusted openings in parts. The sections interlock with the material of the opening, forestalling pivot. They can be crashed into place physically or with the assistance of a hammer or press.

Could Grooved Dowel Pins Be Taken out?

Indeed, grooved dowel pins can be taken out by applying power to push them into a more healthy place. Nonetheless, assuming that the notches have profoundly drawn in with the material, expulsion may more test.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free